… or that’s the way you hack ’em!

Intro

Some time ago (meh, this sentence is in every post…), I was working on an Apple Image Writer dot-matrix printer as a peripheral for one of the Macintosh Classics that I’ve covered on my blog recently. To my surprise, the printer itself was not the main problem, the cartridge for it was! So, today’s post is mainly about restoring dot-matrix printer ribbon cartridges. The method of cartridge refurbishing is pretty much the same for every dot-matrix printer and can be applied to other printers too. Let me start with some background work first 🙂

Apple ImageWriter II

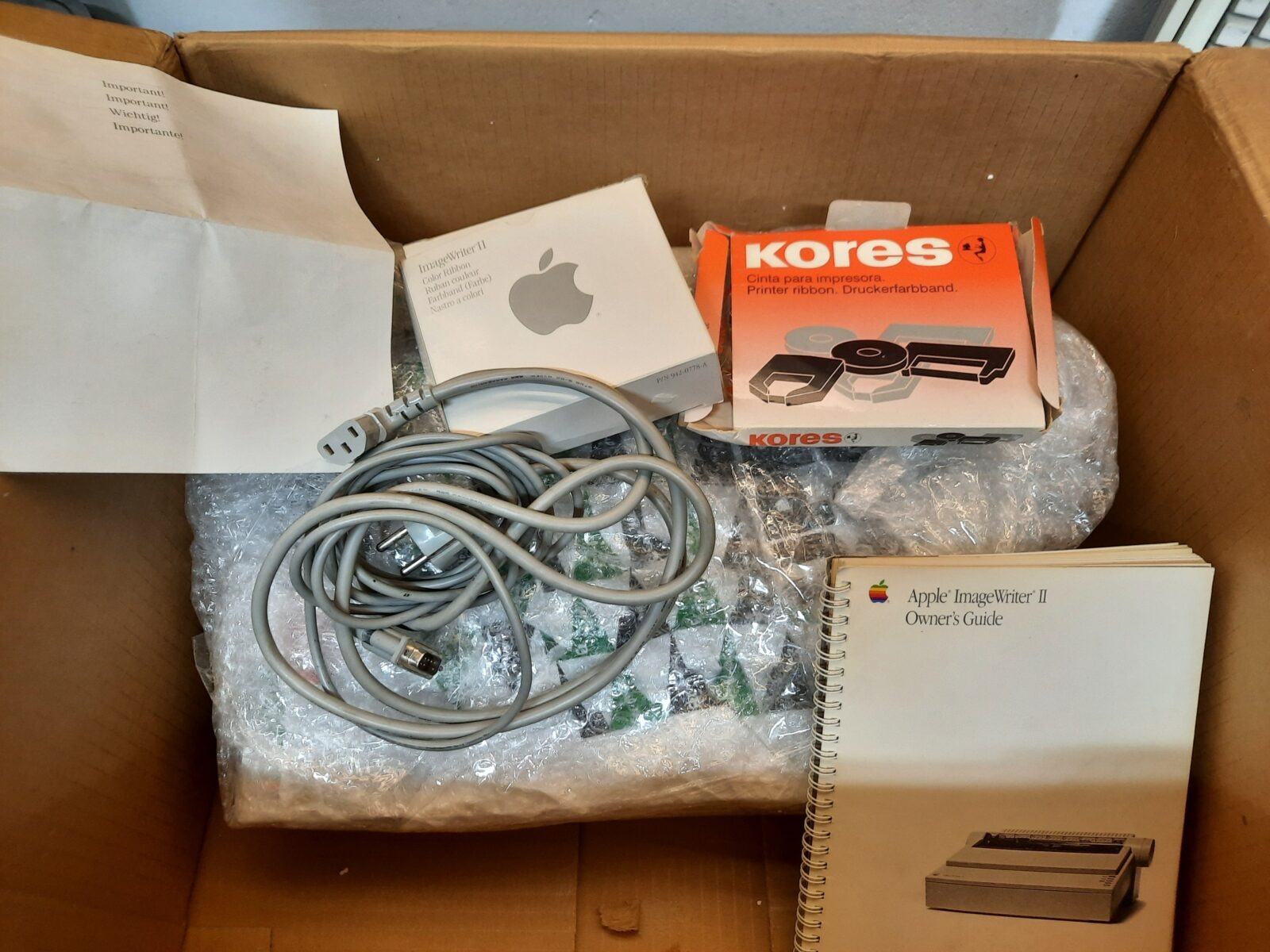

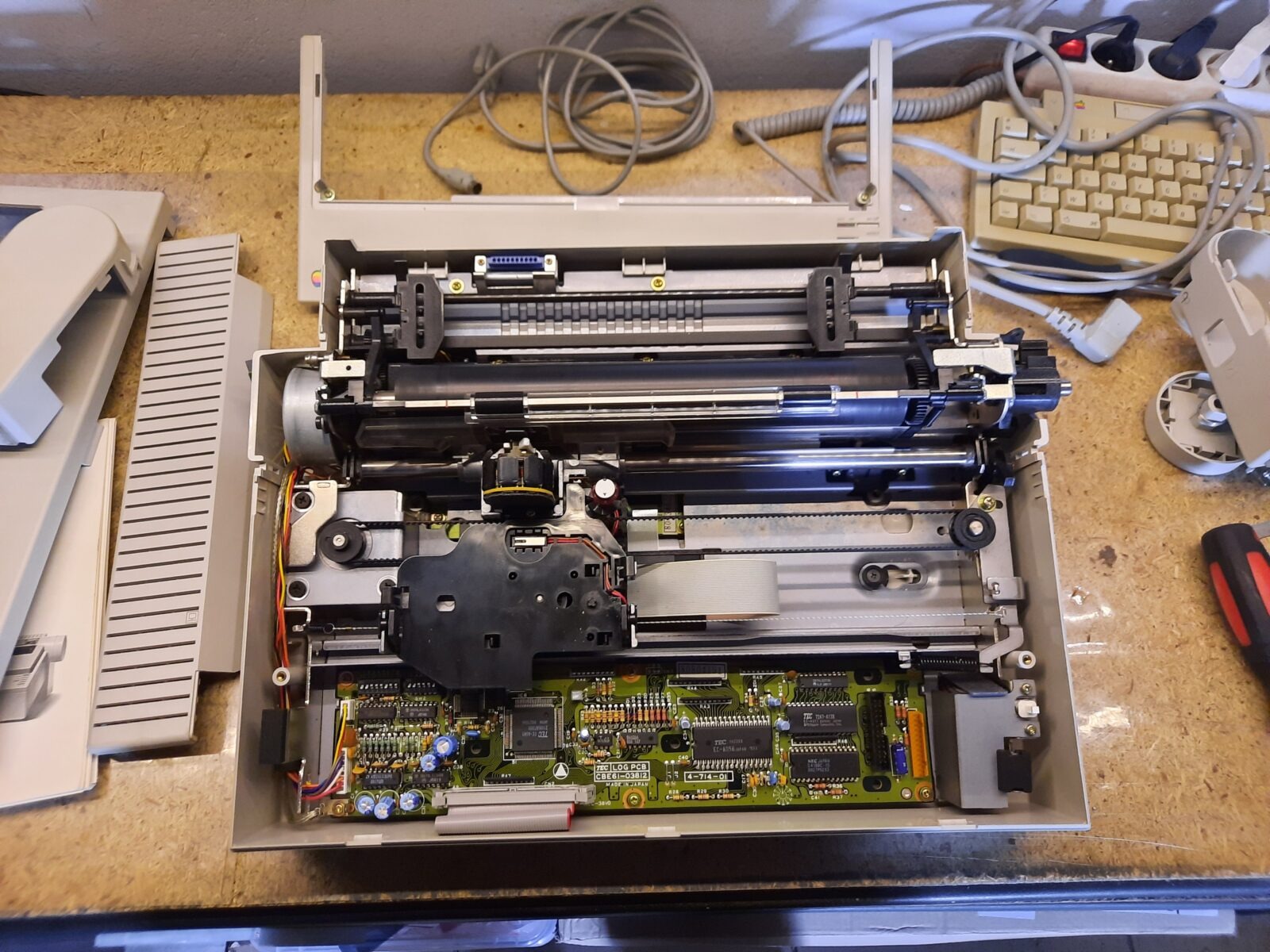

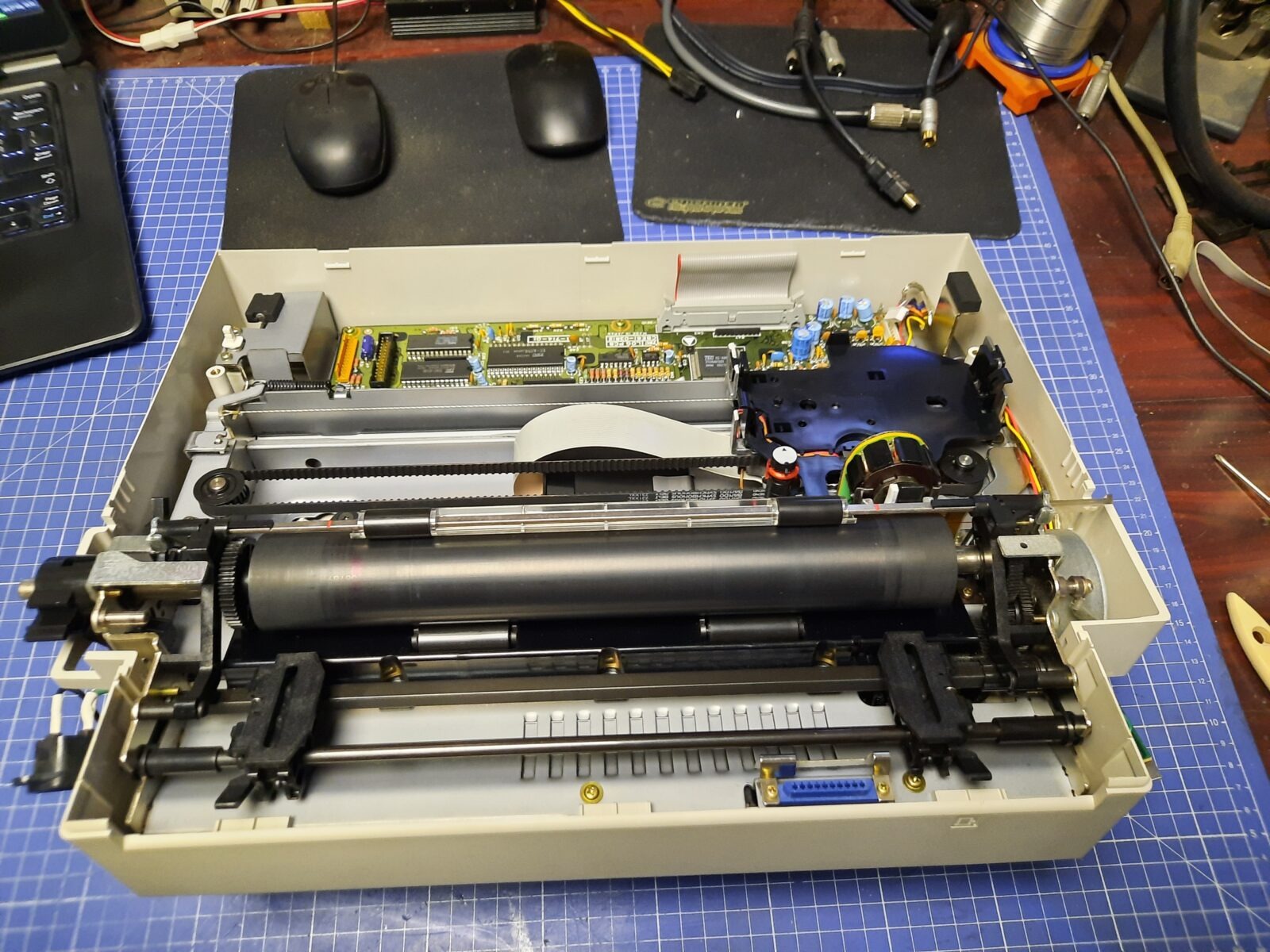

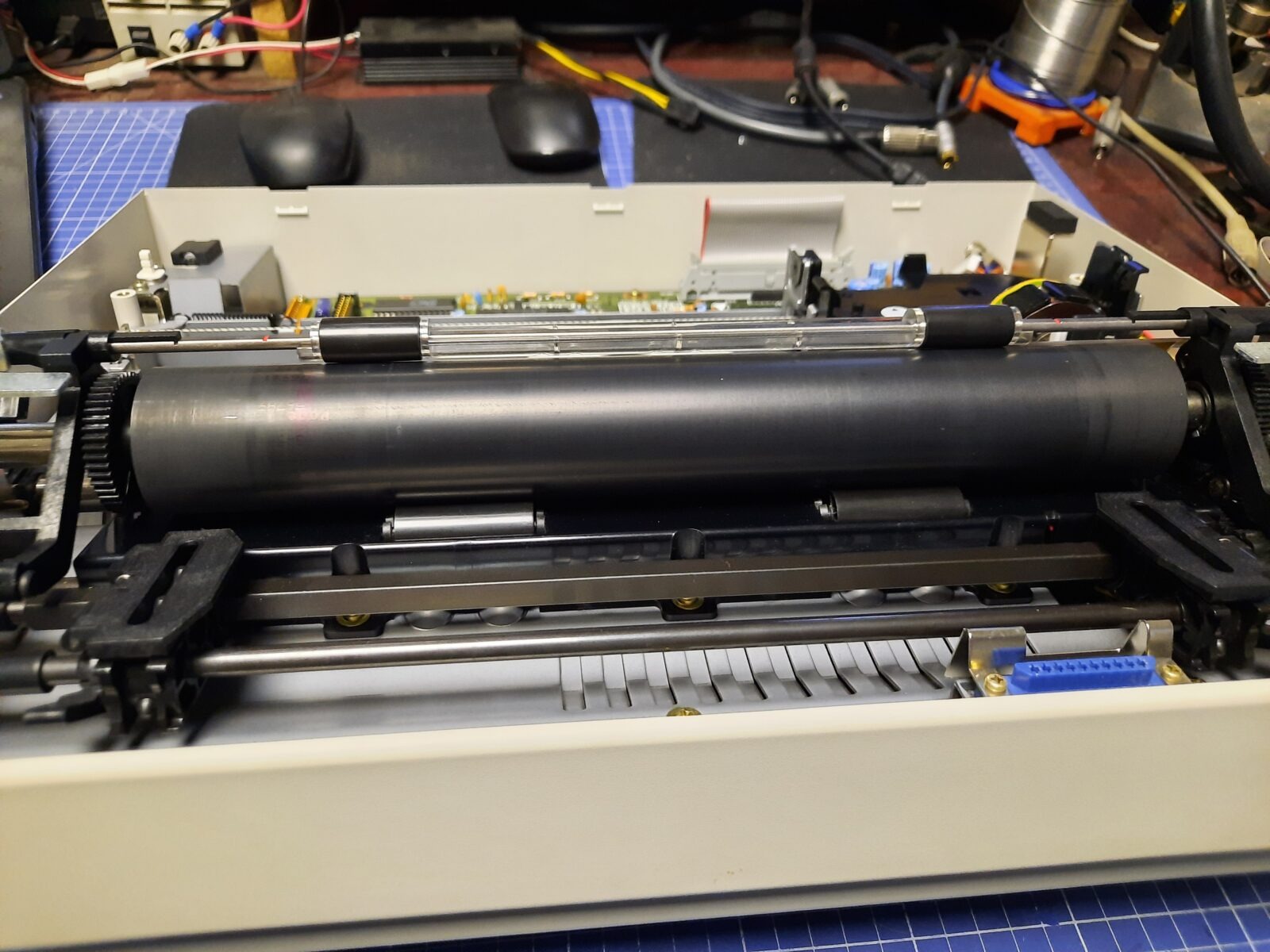

Ok, today’s patient came in very good condition – it wasn’t even yellow. It only needed simple de-dedusting and cleaning … or so I thought.

As usual, after unpacking it, I disassembled and cleaned it. Nothing fancy, just a standard procedure.

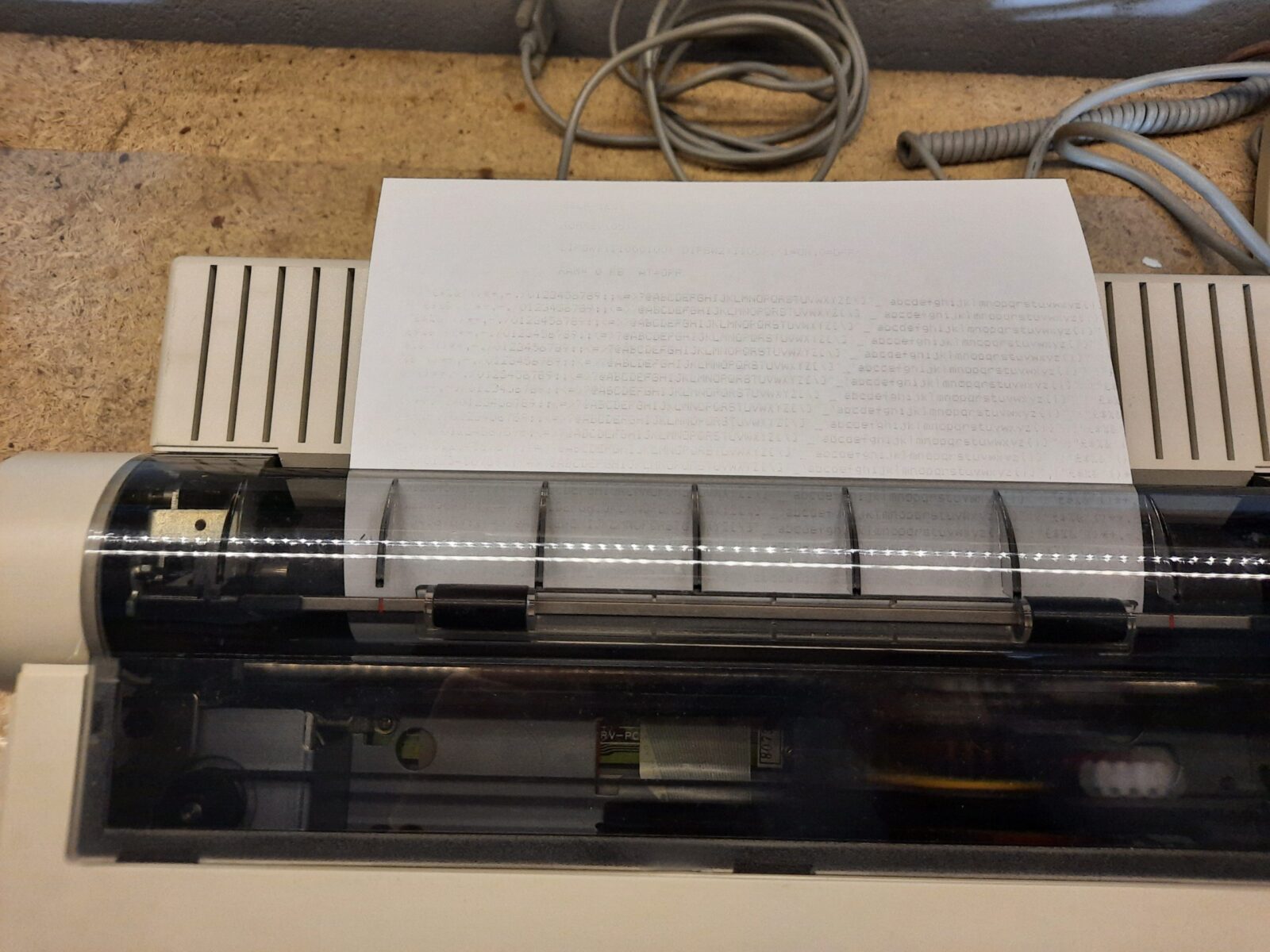

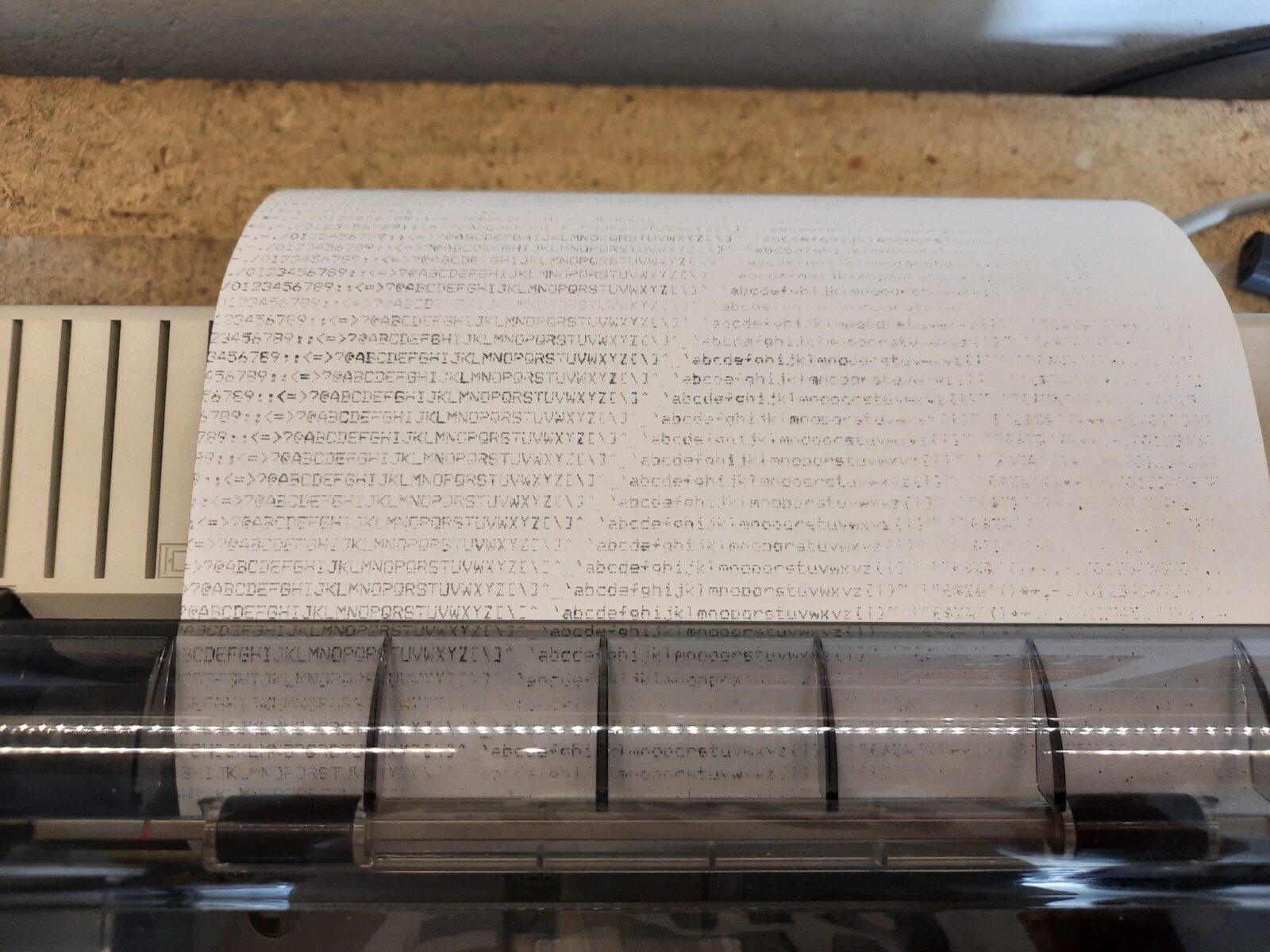

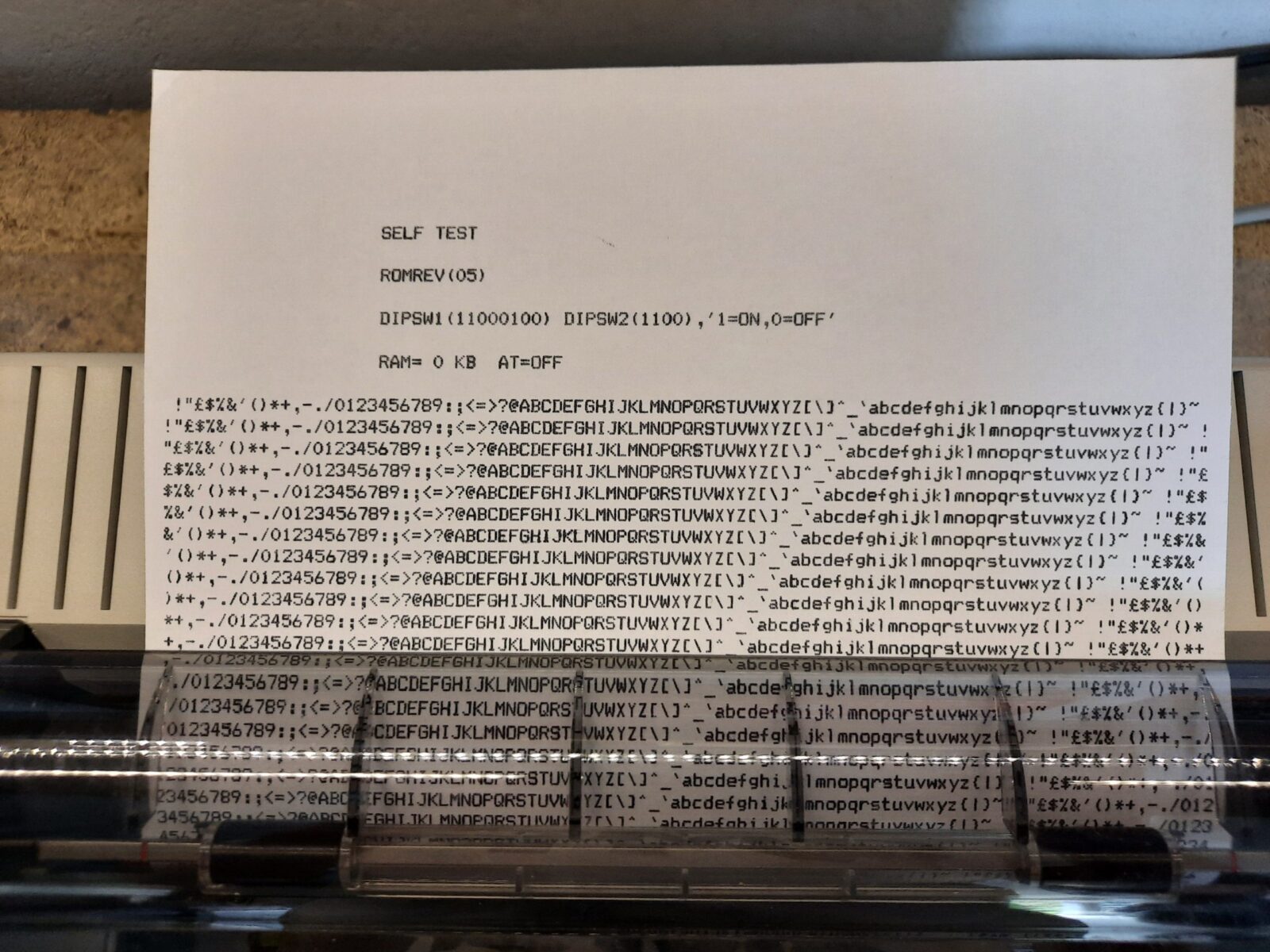

Then, I run some tests and this was the output …

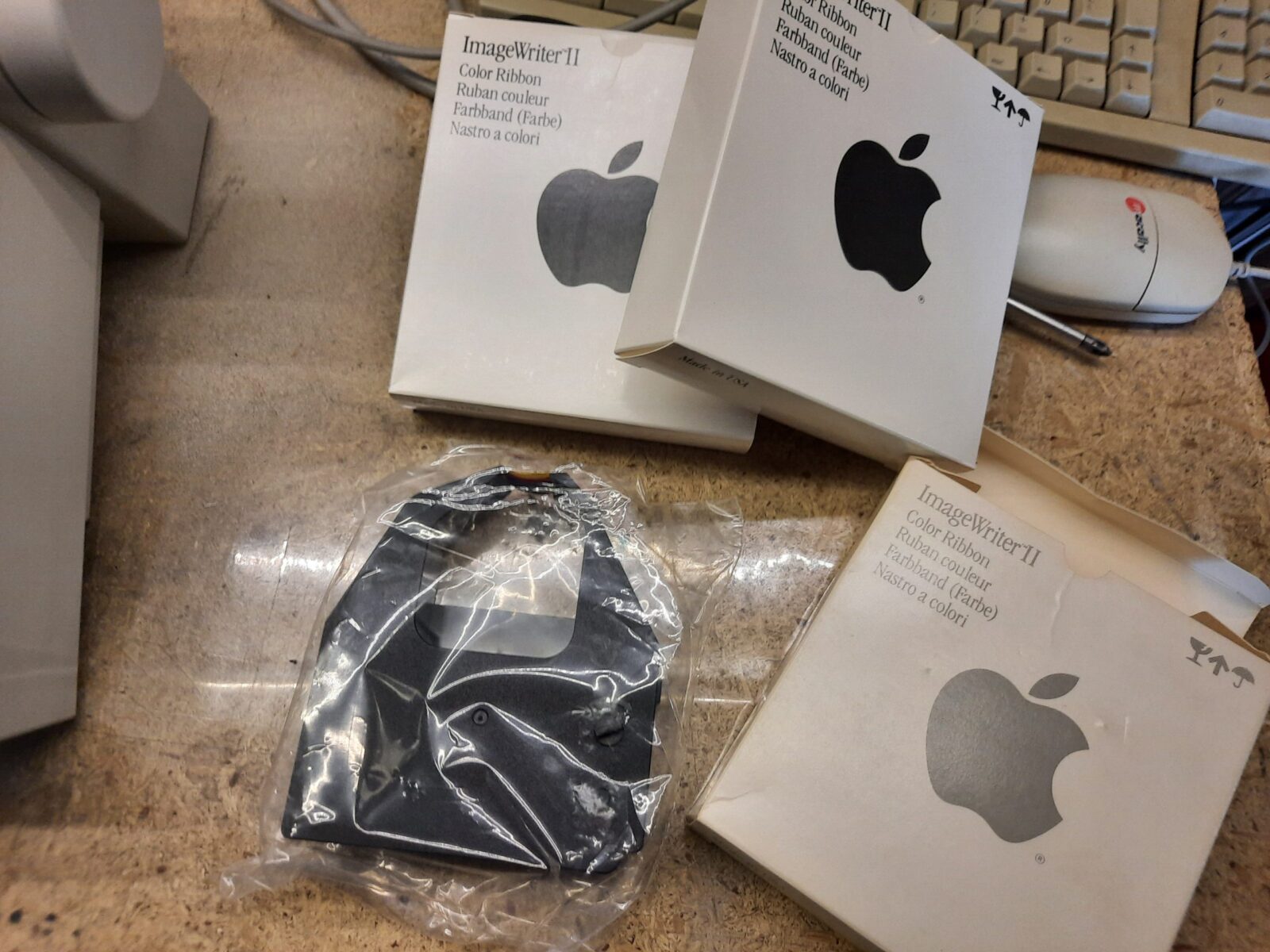

This cartridge dried out so I installed a fresh one but the result was similar. After testing four cartridges, I lost hope and had to start working my way through them. YAY! 😀

Black ribbon cart

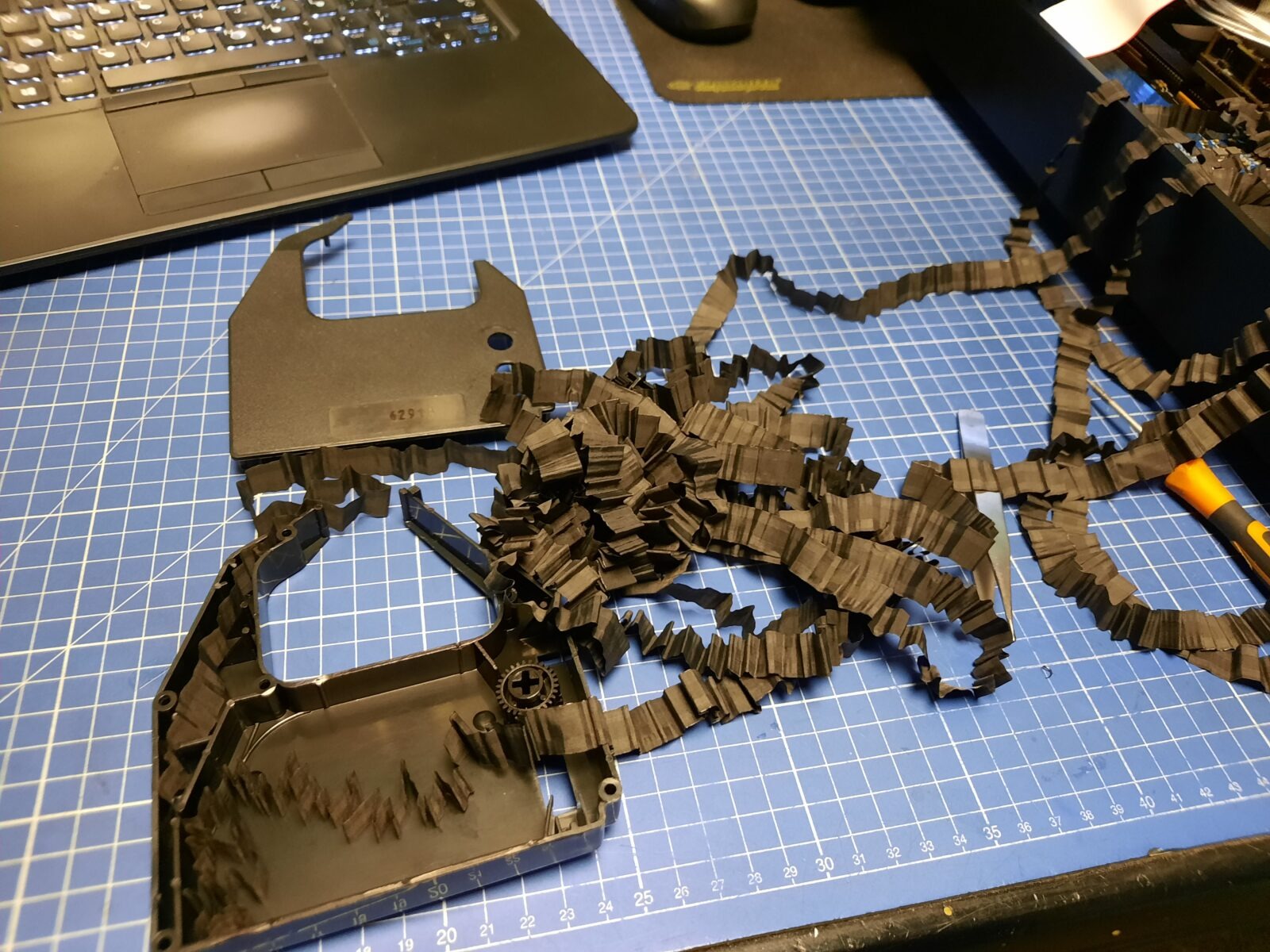

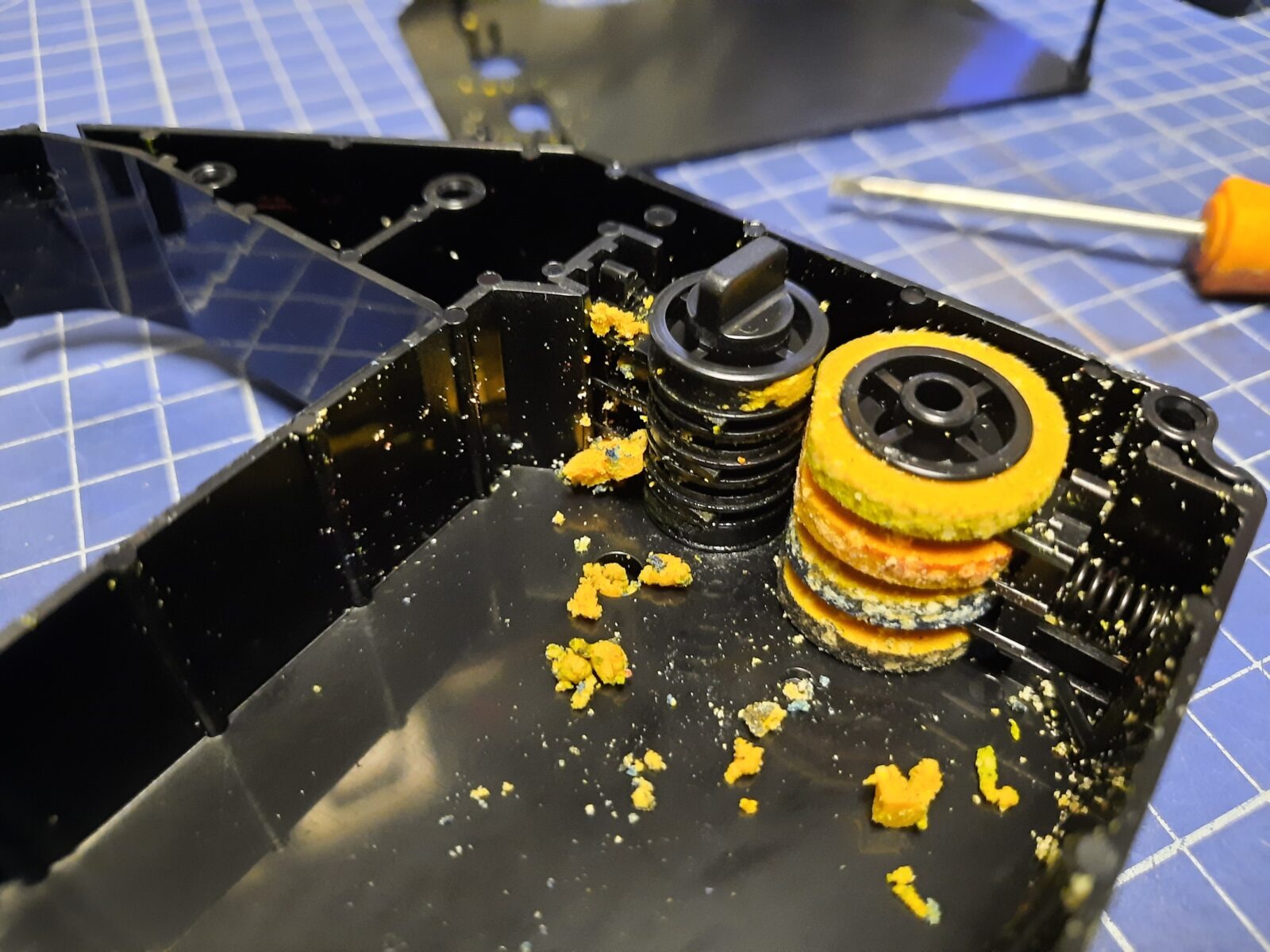

At first, I decided to disassemble the black ribbon cart to simply learn how it was built.

Then, I reassembled it using a screwdriver and moved on to my first attempt at restoring it with black ink.

That was such a spectacular failure after all that work 😀

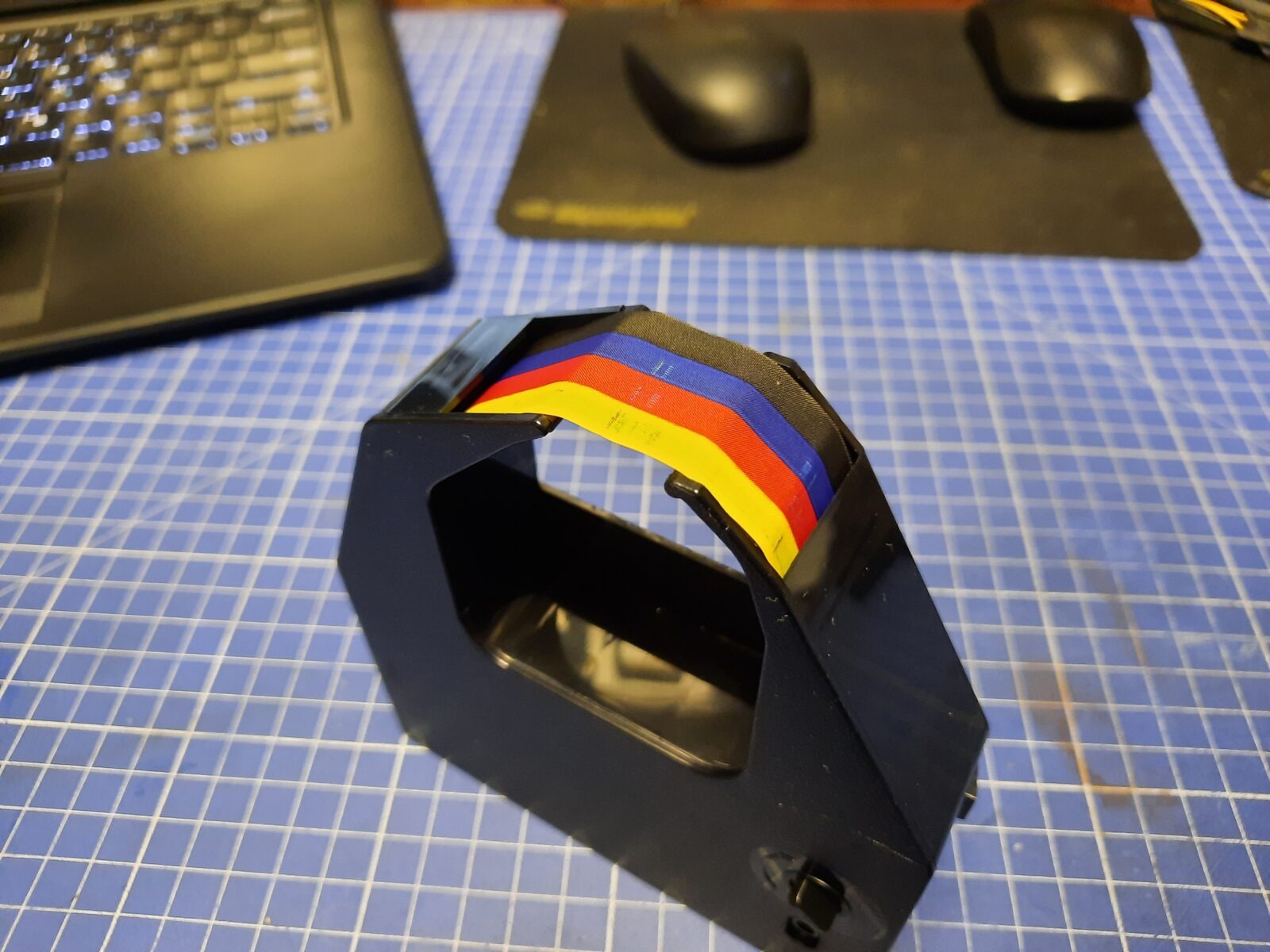

Color ribbon cart

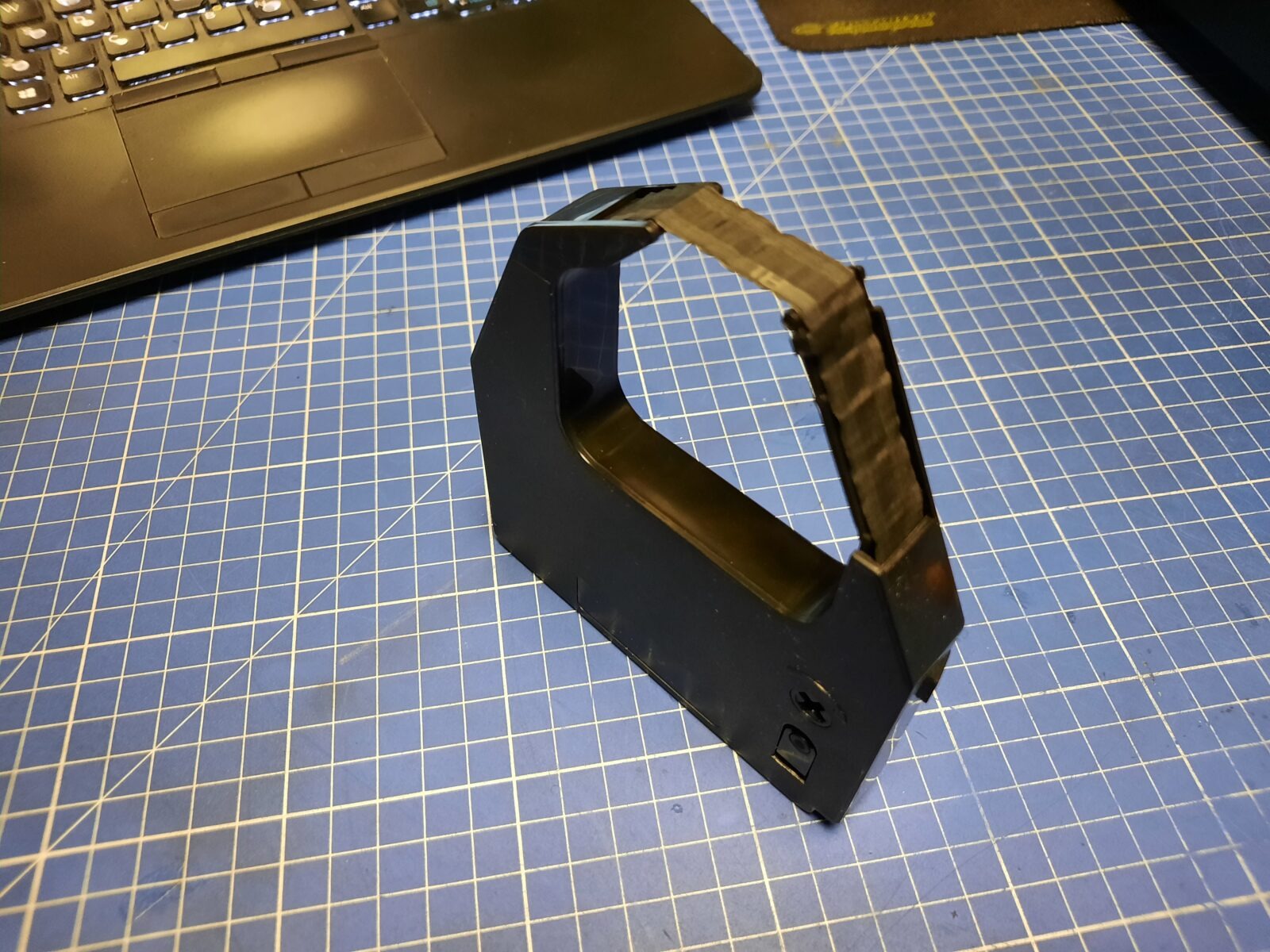

I’ve moved on to color ribbon cartridges hoping I will be more successful with them as I had three NOS cartridges aaaand … I was wrong again lol.

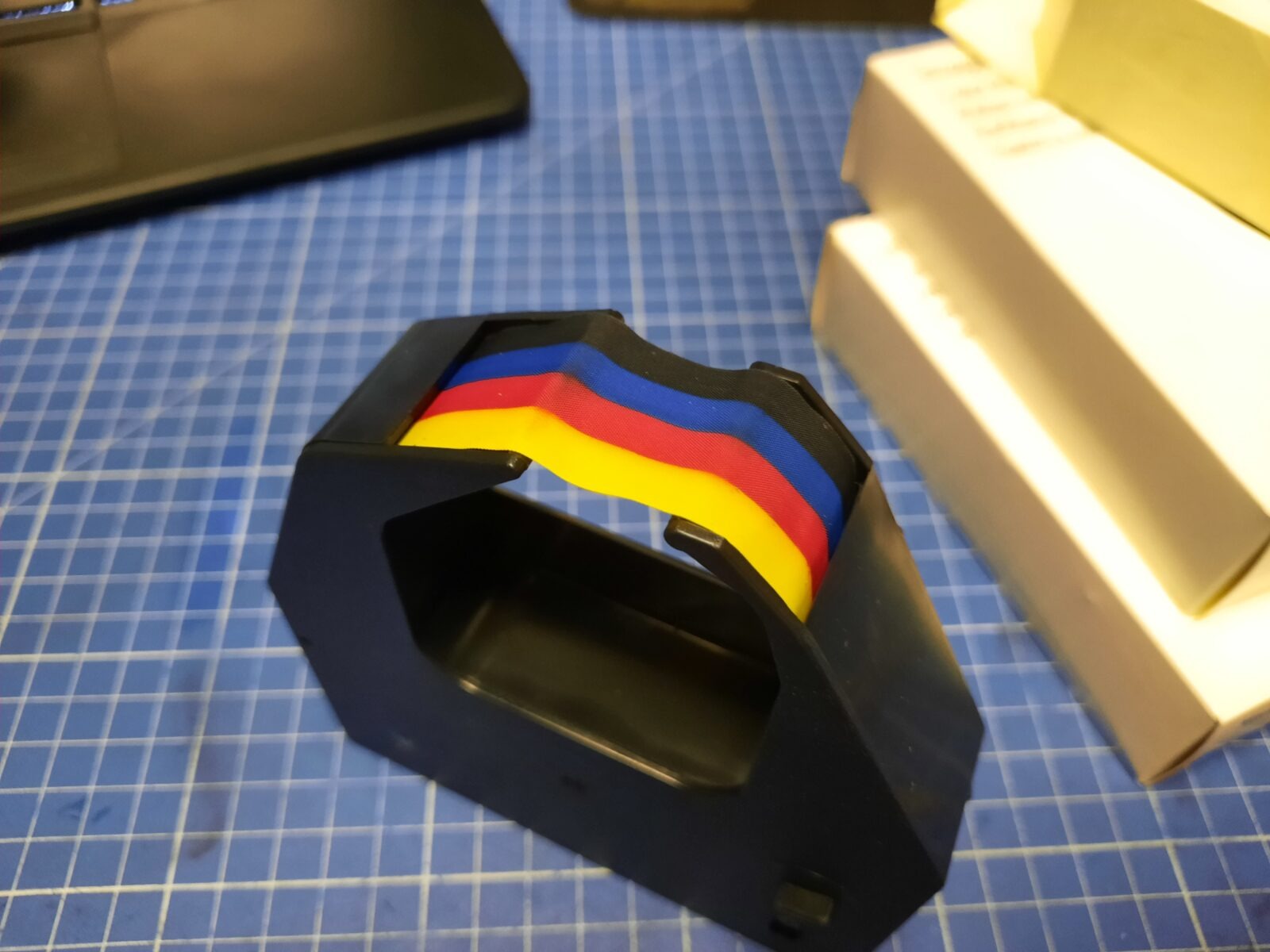

This is the cartridge that came along with the printer itself.

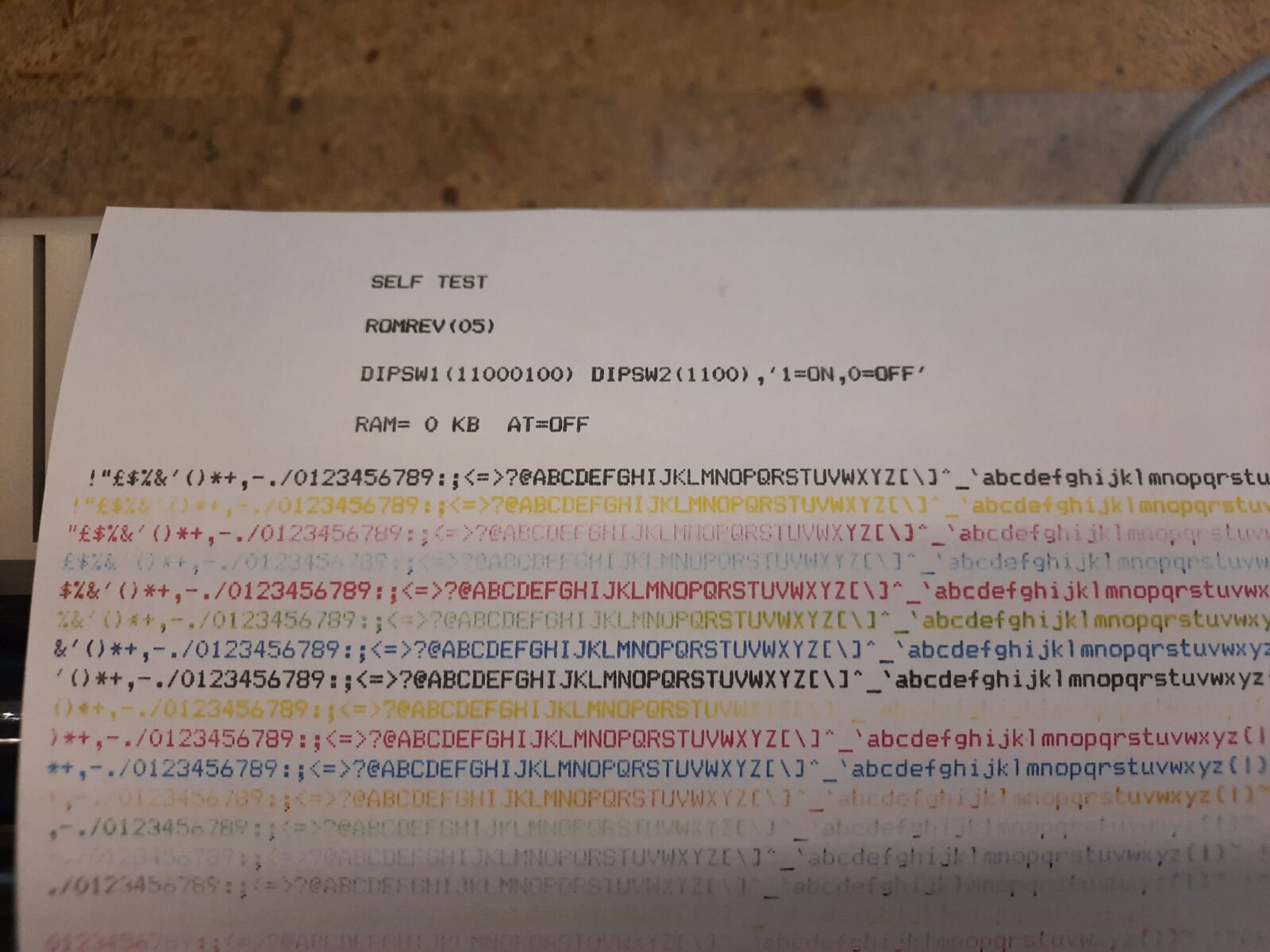

… and this is how it prints err, I should say “printed and stopped printing at all” …

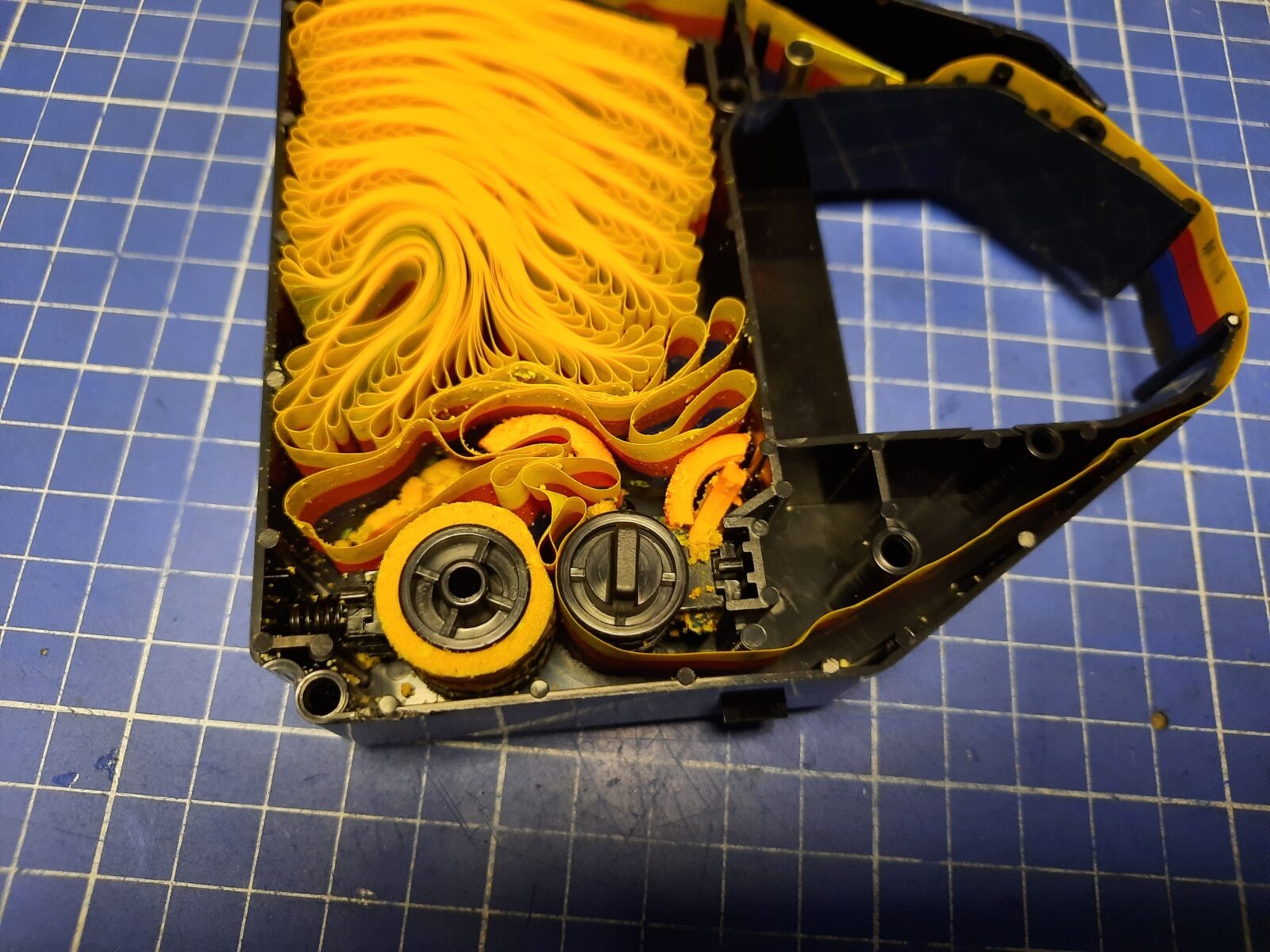

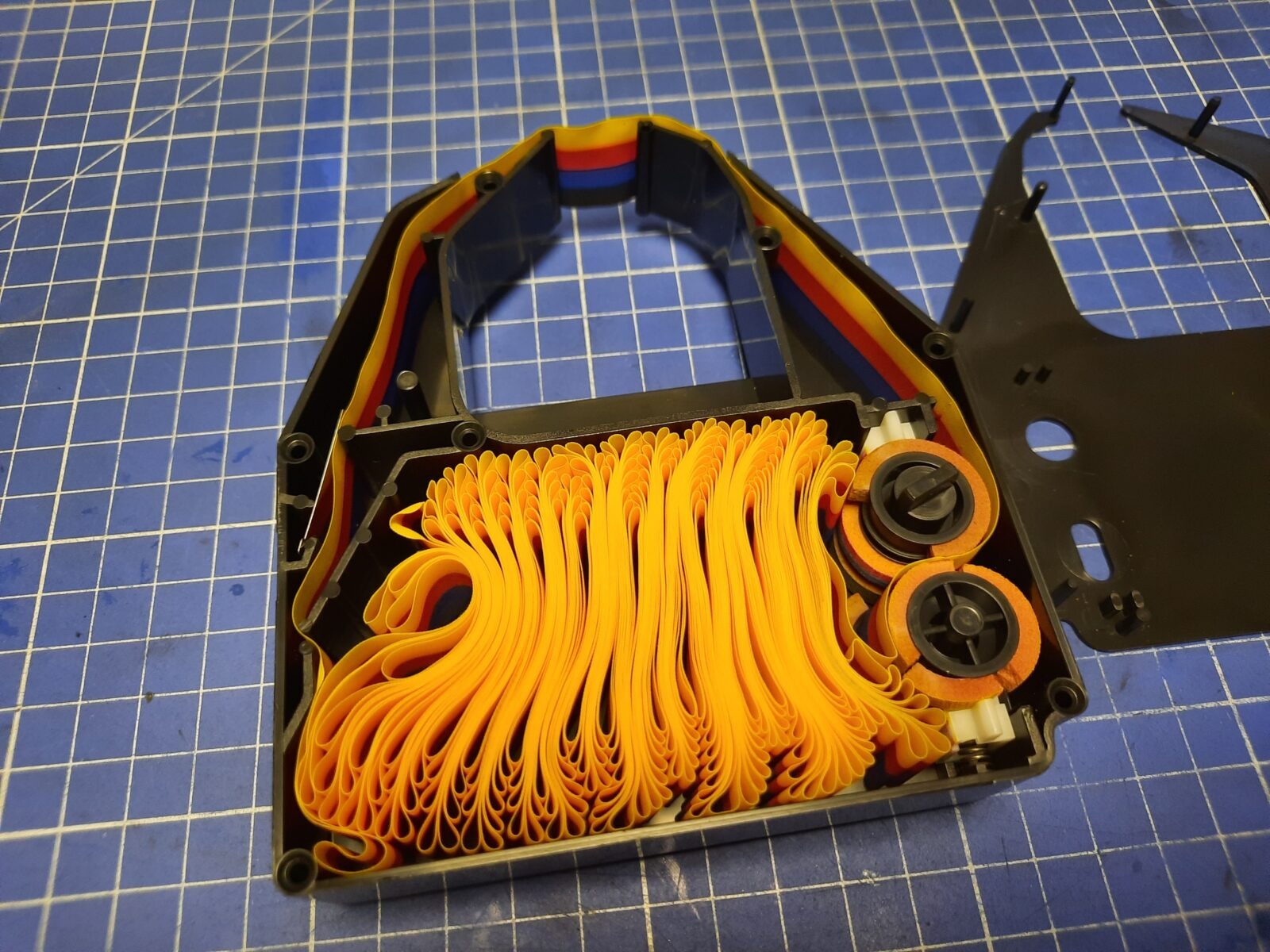

Disassembly followed quickly and I was like AHA! So that’s why!

The rolls were disintegrated.

I was like “Let’s test NOS cartridges then!”. However, I was wondering why these NOS carts had turn marks on the polyethylene bags in which they were wrapped.

No, no luck with this one either. It now was obvious why these turn marks were there. Simply put, the eBay seller knew that these carts were dead by simply turning a knob and he still sold them as brand-new, NOS units.

Same story with another cartridge.

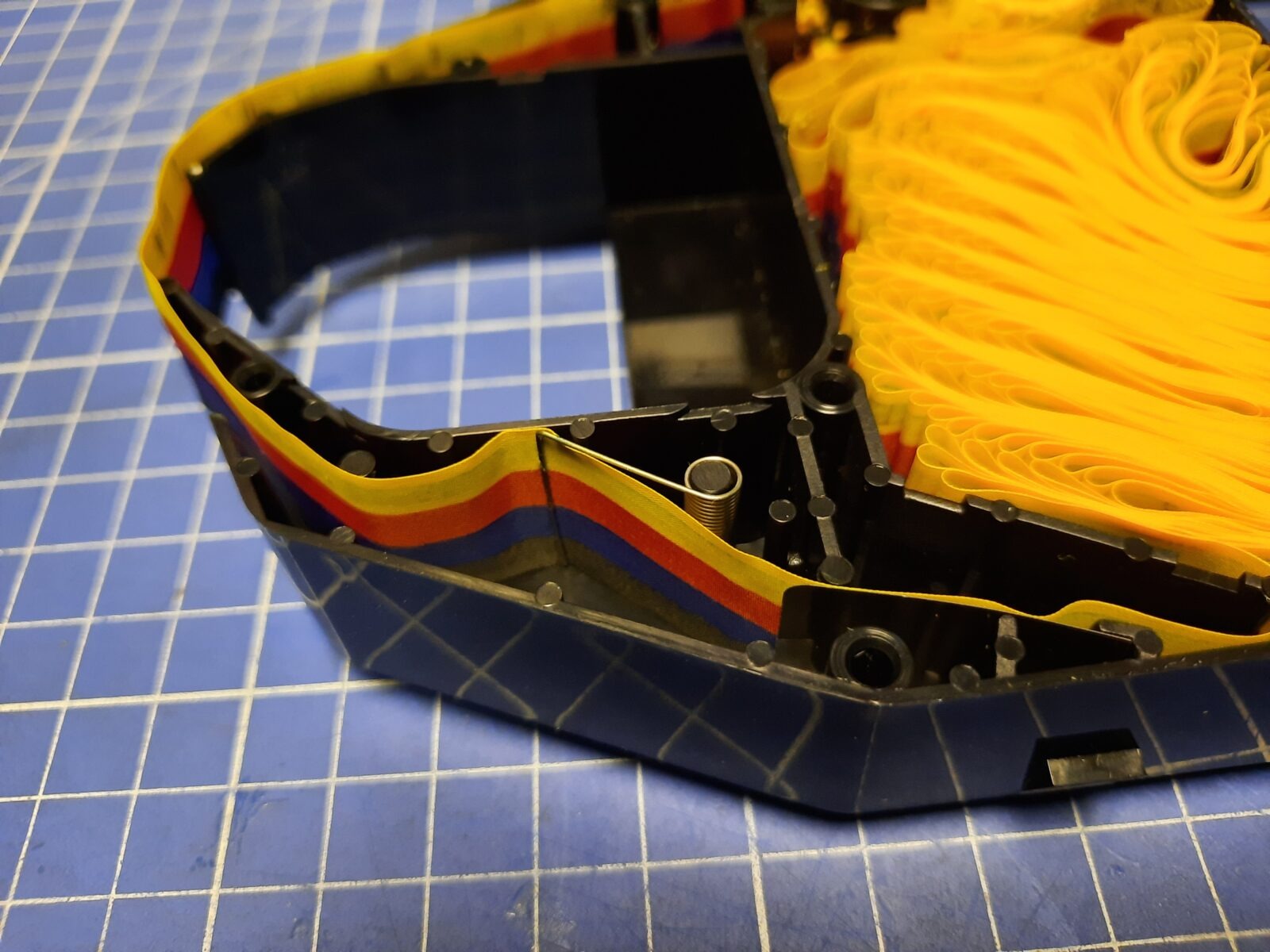

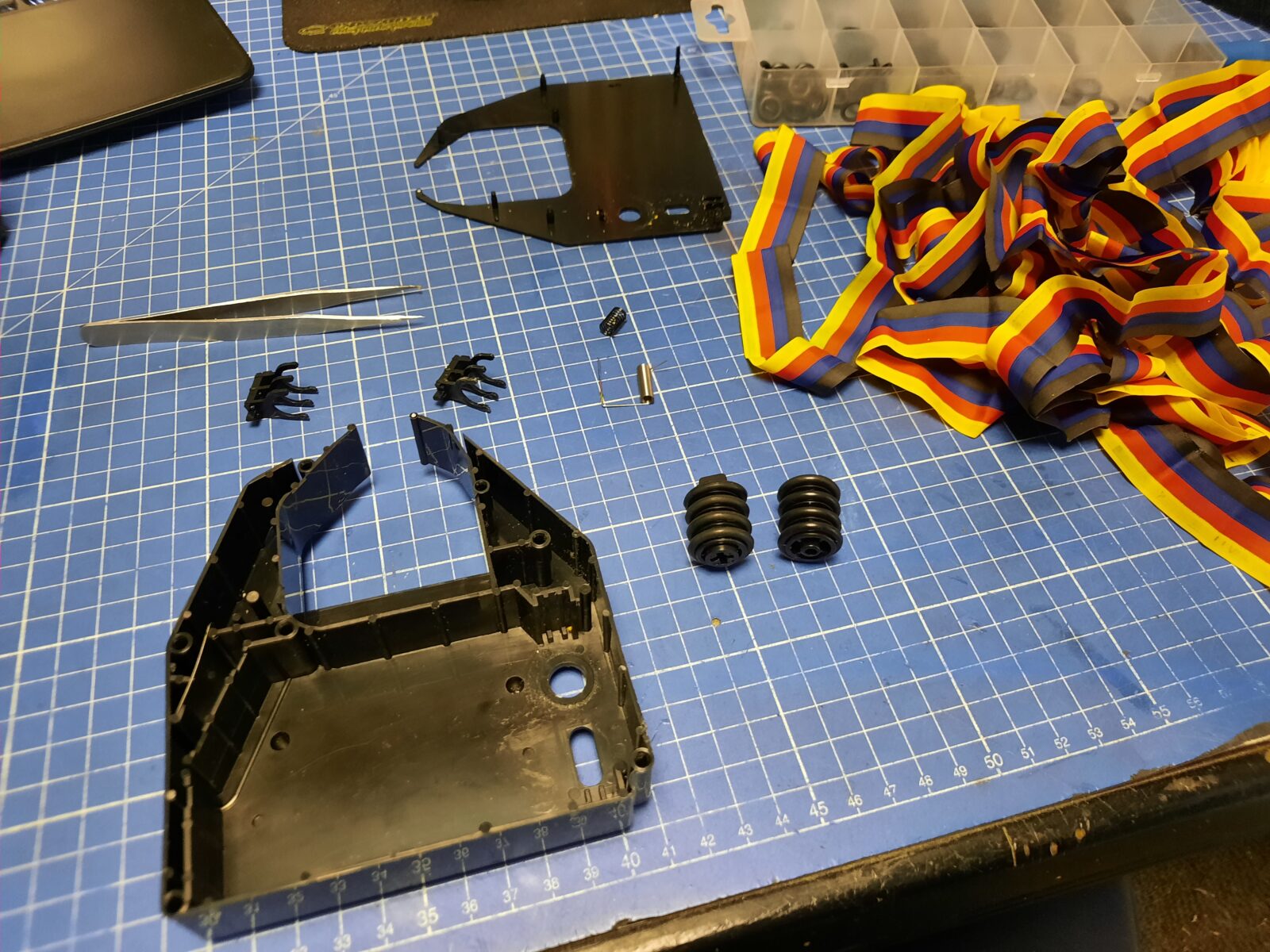

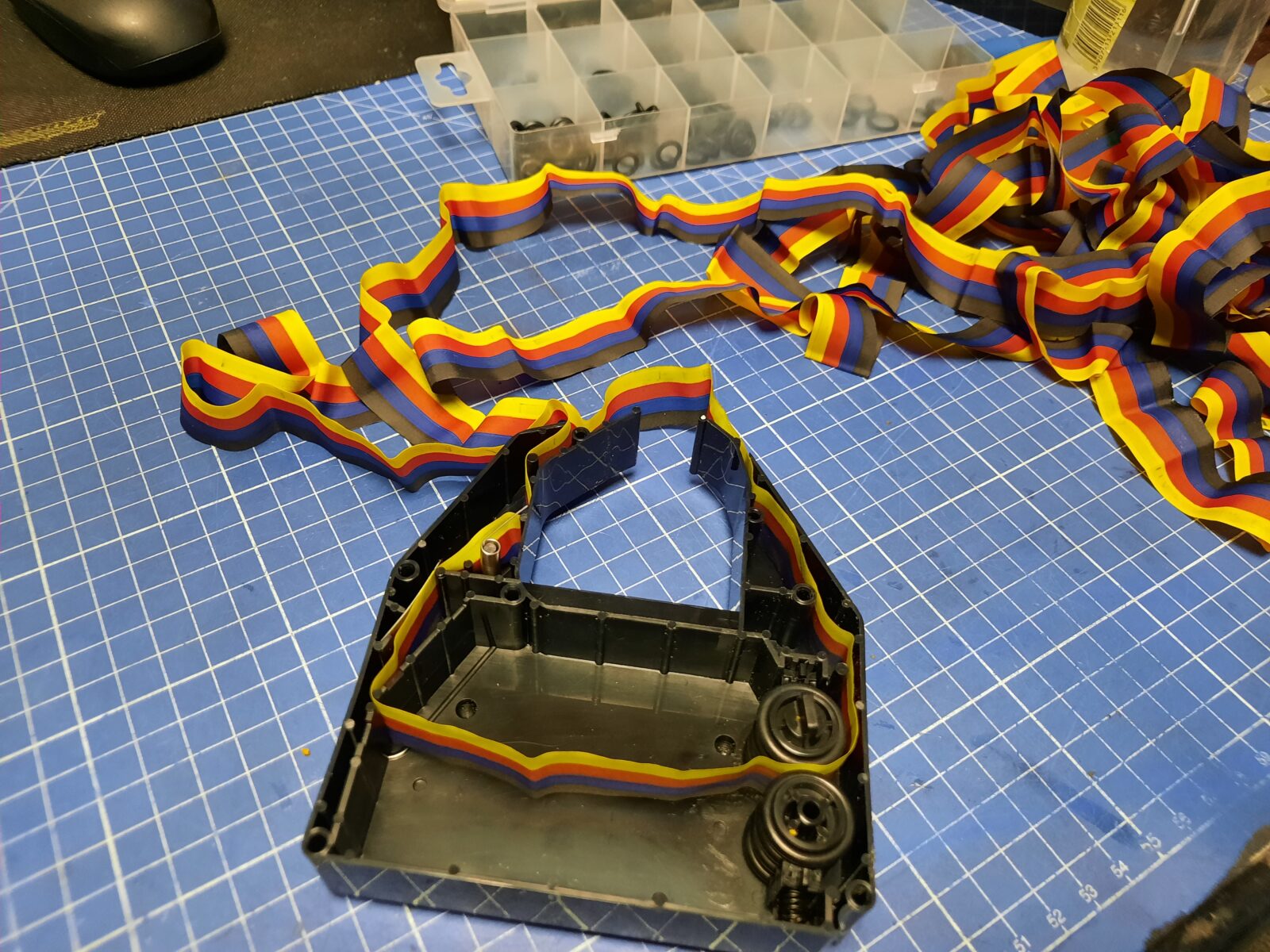

The rolls fix

It took me a while to figure out a cool hack to fix these rolls but once it was done, it works like a charm.

The idea was to replace the original foam rolls with simple, rubber O-rings used so widely everywhere.

I’ve used a generic O-ring – 13×3 mm

Here is how it all looked.

After some testing, rolls started to work again as seen in the above video, but it still didn’t print properly and this is where we are nearing the final hack 🙂

The final fix

After a lengthy research on this topic, it turned out the final fix is straightforward. I’ve found out that applying mineral oil evenly onto ribbon restores its properties!

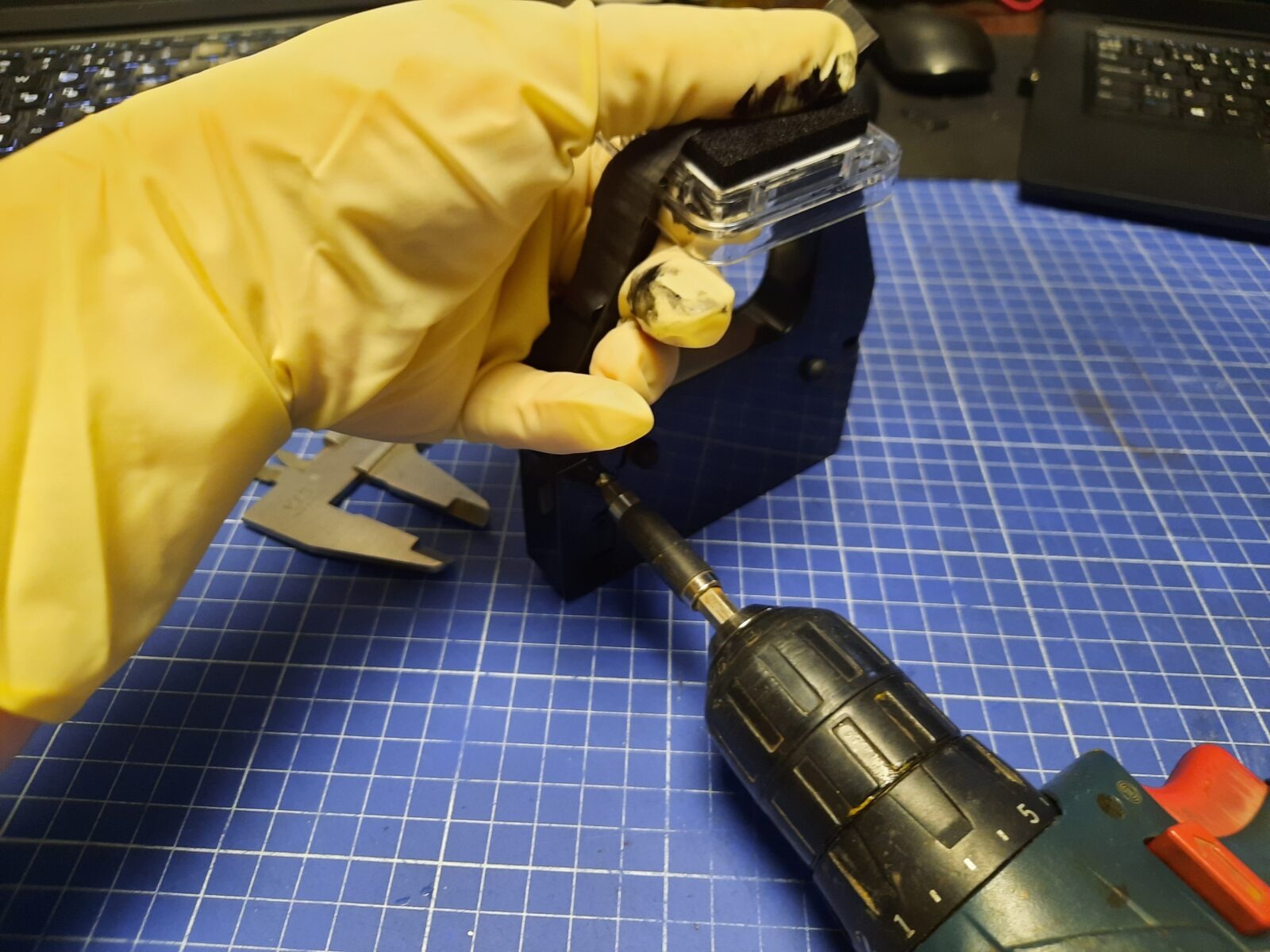

Vaseline oil did the trick in my case as it doesn’t stink and doesn’t have any color. I’ve applied it to both black and color ribbons and it worked perfectly fine! The application method is pretty much the same as in the pic above where I showed how I did it with black ink. You just need a pair of rubber gloves, a piece of sponge, and an electric screwdriver 🙂

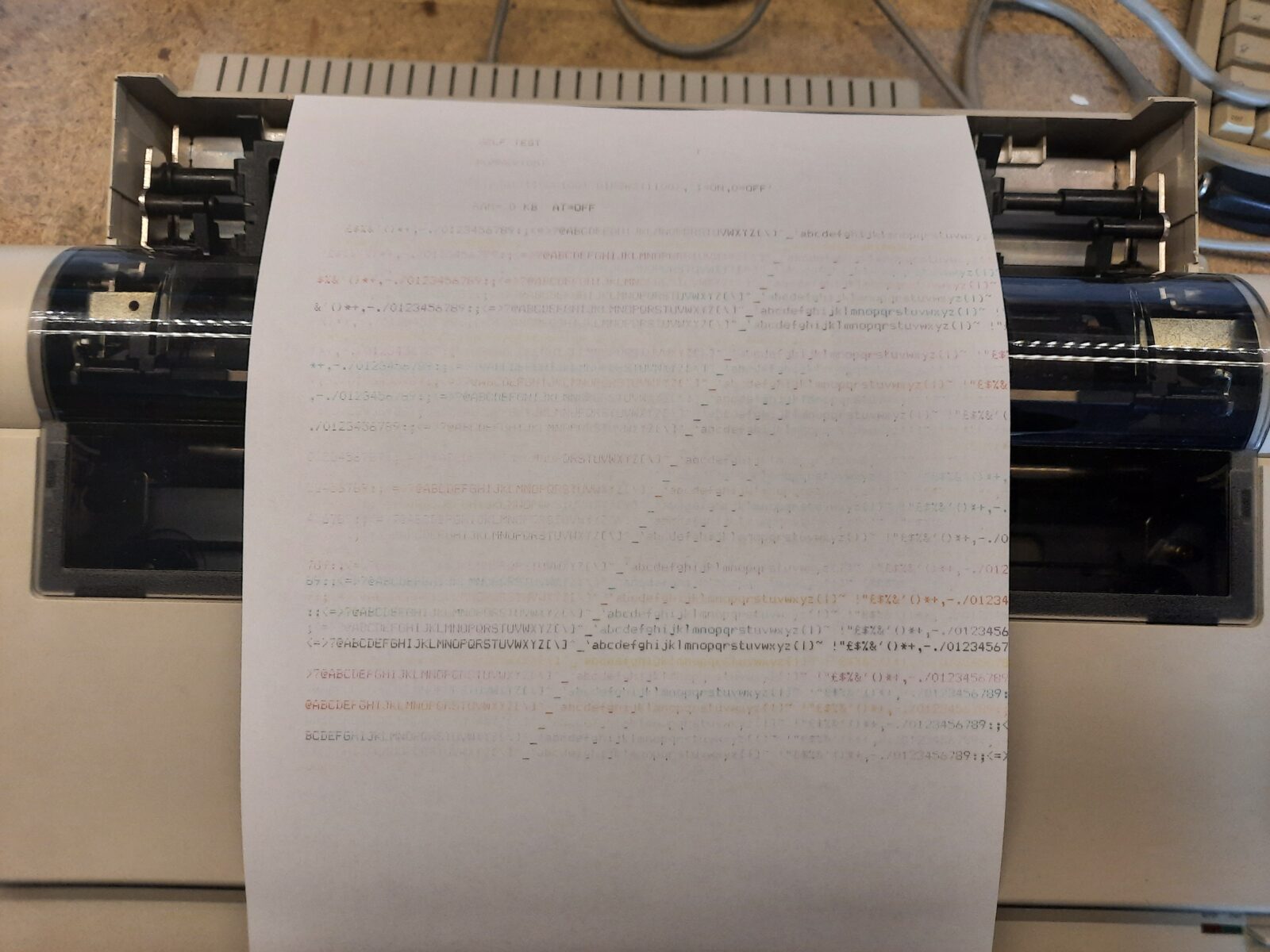

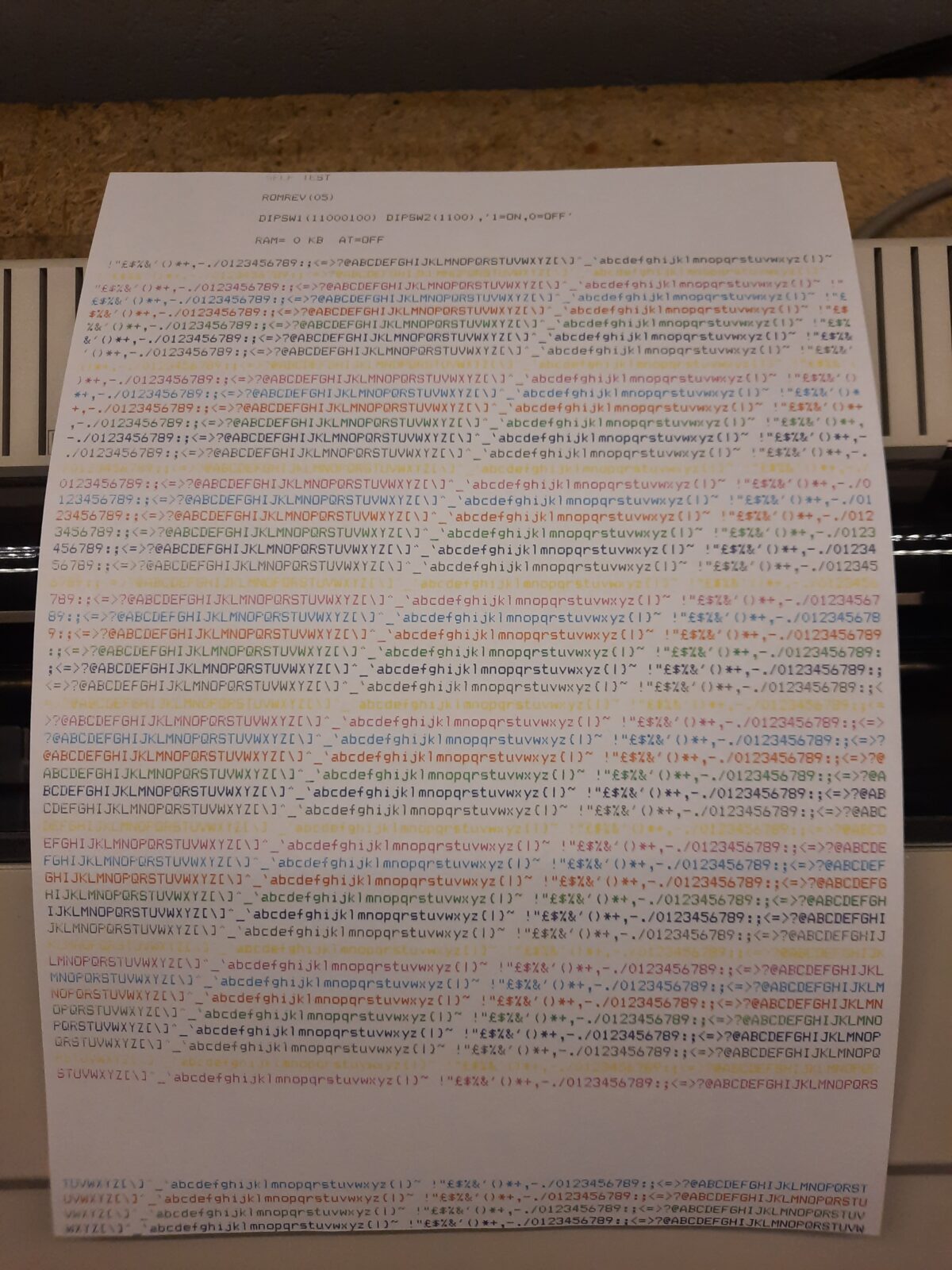

The results speak for themselves! 🙂

After a few passes it stabilized and started to print full lines nicely!

The end

It’s just so simple, apply some mineral oil to a ribbon and it starts to print properly. This is how restoring dot-matrix printer cartridges helps to use such printers in 2023 when new cartridges are nearly impossible to get. Even if you manage to get them, most of the time these units are degraded. Fortunately, as seen above, there are ways to fix them 🙂

This is it for now. See you in the next post and always remember – Nothing is ‘unrefurbishable’ 😀

Outro

If you want to get the retro gear I am manufacturing or hardware modules, please visit shop -> https://retrohax.net/shop/

Please support my work by commenting here, and on my Facebook, Twitter, Reddit, and other social media platforms.

This is great information, thanks! I have Commodore MPS-1224C and 4-colour ribbons that I’ve stored since the 90s, so it’s highly likely they need restoring too. For some reason I couldn’t find vaseline oil from local shops, but I guess this product is suitable: https://mts.ee/en/toode/ag-termopasty-vaseline-oil-100ml-oil-can-ag-agt-018-328005283

Oh, it doesn’t have to be vaseline oil. I just ha it on my shelf. I think you can use any other mineral oil, I would even say that baby oil is ok 😀

Hi.

It’s been a year since you applied oil to the ribbon. Are they still working fine?

Regards

It is rather a question to a client who uses it. I don’t have it here anymore, however, I don’t see a reason why it would not work fine.

That is great.

I still think about the magic of printing back then. Usually, in the 8bit-era, you had to to select the font on the PRINTER!!

The first adventure games like Zork were played on a printer rather than on a display.

Stories like this one bring back such memories.

Thanks a lot for saving this wonderful old device!

Thanks! I remember I had Epson as a first printer but I’ve no idea what model it was.

What size 0-ring (id X thickness or AN number) did you use for the colour cart?

I will measure it tomorrow and let you know.

Ok, it took me a while longer 😀

Generic O-ring 13×3 mm

Thank you for the hint! I thought you will use some special inks still possible to buy, but vaseline oil is a much better choice for us. Also giving the solution to the roller wheel is an extra. Have a good day!

Thanks for your kind words! 🙂

After a few times of spritzing black dot matrix ribbons with WD-40 I’d dribble stamp pad ink across the wadded up ribbon, replace the top cover then turn the drive around and round until the ribbon had made several passes through and evenly distributed the fresh ink all across its width.

That WD-40 trick is a great idea too. Although, it smells a bit 😀